PVD Coating Equipment for

Precision Surface Treatment

Dimton applies high-tech PVD coating to enhance durability, scratch resistance and surface brilliance for various metal components.

Enhancing Metal Surfaces with Advanced PVD Technology

Dimton applies high-tech PVD coating to enhance durability, scratch resistance and surface brilliance for various metal components.

The Brand behind

Enhancing Metal Surfaces with Advanced PVD Technology

Dimton applies high-tech PVD coating to enhance durability, scratch resistance and surface brilliance for various metal components.

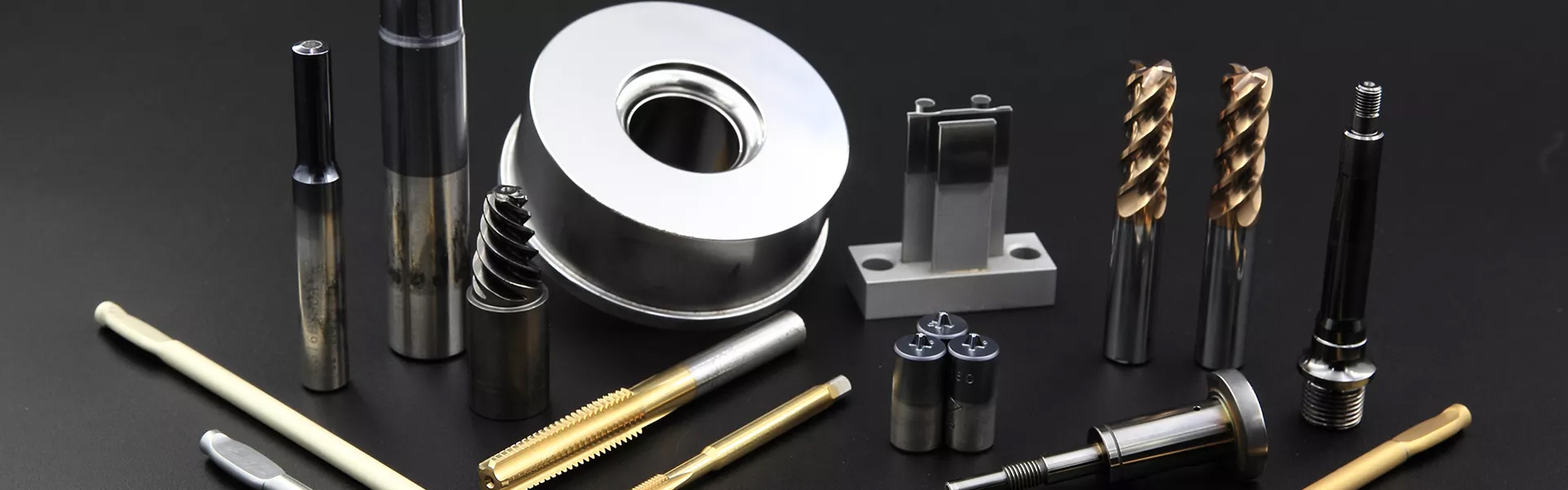

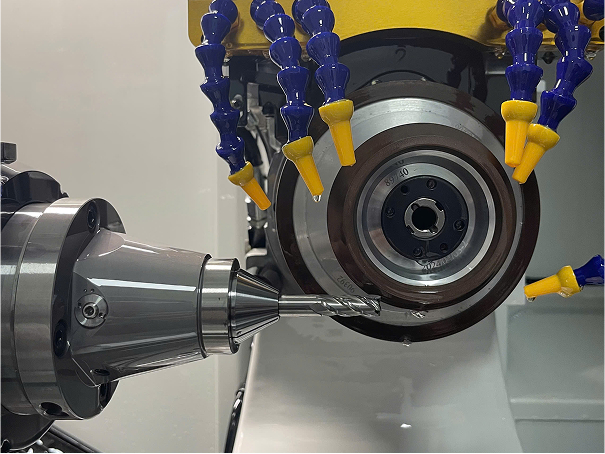

PVD-Coated Drill Bits for Maximum Durability and Precision

Improve tool efficiency and reduce replacement costs with our advanced surface coatings for drill bits and cutting tools.

about us

Common coating techniques are shown in the figure, ranging from traditional electroplating to today’s vapor phase methods, such as physical vapor deposition(PVD) and chemical vapor deposition(CVD). As the industry progresses, the requirements for the quality of the film are also raised. Compared with the traditional electroplating method, the vacuum environment can ensure that no other substances are added to the film during the process. In today’s high-tech industry and the high-quality requirements of the semiconductor industry, vacuum coating technology is the most suitable coating technology, and it is also a key technology for high-tech industries.

year of establishment

Foreign investment

Leading technology

Our serviecs

Delivering advanced surface coating solutions with precision,

durability, and international expertise.

pvd coating

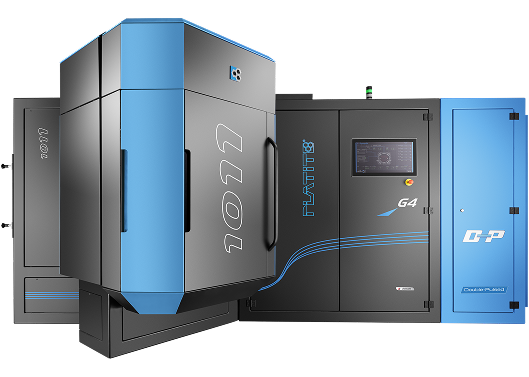

KEY BENEFITS OF PVD COATING – POWERED BY PLATIT TECHNOLOGY

· Enhanced surface hardness without compromising part quality.

· Superior wear resistance for cutting and forming tools.

· Improved oxidation resistance via protective surface layer

· High friction tolerance with reduced friction coefficient

· Extended metal lifespan and minimized surface deformation

· Eco – friendly process – non – toxic and emission – free

CNC Milling Tool Regrinding

Revitalize Cutting Tools – Extend Life, Cut Costs

– Extend tool lifespan and reduce replacement costs.

– Ensure high machining surface quality and precision.

– Minimize downtime and maximize production efficiency.

OEM Milling Tool OEM Production

Custom CNC Tools – From Drawing to High-Performance Finish

– Reduced production costs and lead times.

– Enhanced production efficiency and tool reliability.

– Support for brand customization (logo, laser engraving, packaging).

HARD COATING APPLICATIOn

TiN

TiN

Content is being updated!

TiAlN-high titanium

TiAlN-high titanium

Content is being updated!

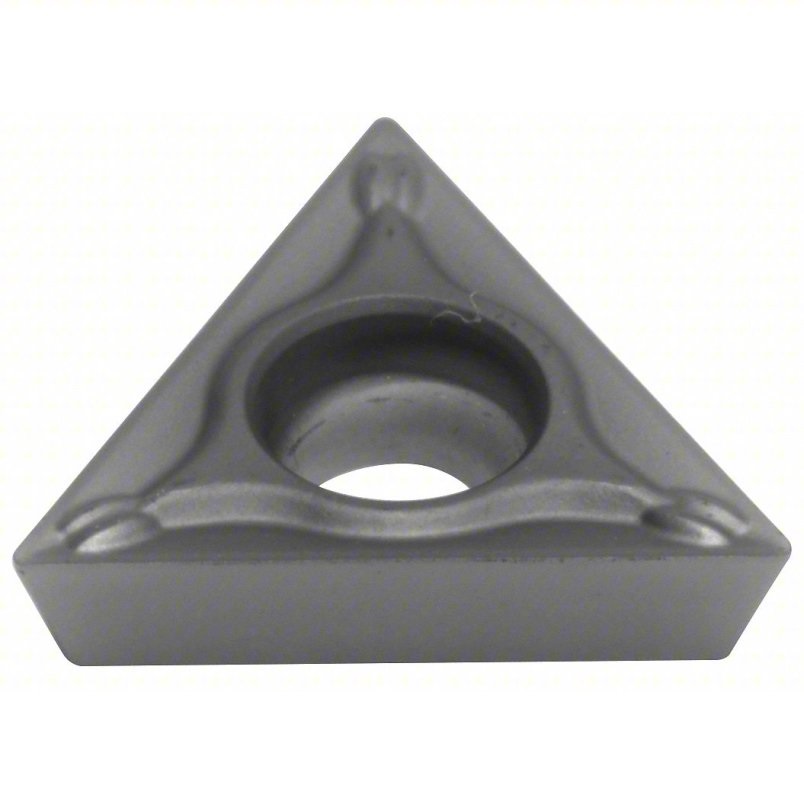

SUMITOMO

SUMITOMO

- Primary Material Application Nickel : Titanium

- Inscribed Circle : 1/4 in

- Cutting Direction : Neutral

- Thickness : 0.0937 in

- Corner Radius : 0.0312 in

- Chip-Breaker Code : ESU

- Clearance Angle : 11 °

- Finish - Machining : AlTiSiN

- Insert Style : TPMT

- ANSI Code : TPMT21.52ESU

- ISO Number : TPMT110208N-SU

- Number of Cutting Edges : 3

- Chip-Breaker : Yes

- Chip-Breaker Style : On One Side

- Coating Process : PVD

HIGH QUALITY PVD PLATED

HIGH QUALITY PVD PLATED

Content is being updated!

HIGH QUALITY PVD plated

HIGH QUALITY PVD plated

Content is being updated!

HIGH QUALITY PVD PLATED

HIGH QUALITY PVD PLATED

Content is being updated!

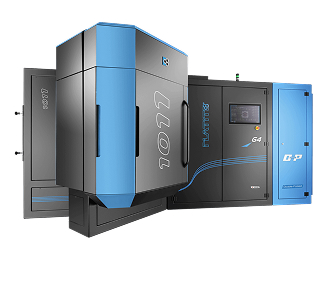

coating system

PLATIT

PLATIT

Content is being updated!

PLATIT

PLATIT

Content is being updated!

PLATIT

PLATIT

Content is being updated!

clients

In Vietnam’s major manufacturing hubs, DIMTON actively provides stable, fast and efficient PVD coating and tool regrinding services, earning strong recognition from the industry. Our service network spans the entire country, covering both the manufacturing and high-tech sectors.

news

Challenges to cutting Tools Solid wood and wood-derivative materials such as plywood, fiberboard, and chipboard present a unique challenge to...

Evolution of TiN-related coatings for cutting tools TiN stands for Titanium Nitride,...

Introduction Depending on service requirements, tools and components can be improved in...